Global Demand Rises For Durable Tile Cutting Machines In Residential Projects

2025-05-16

In recent years, the global market has witnessed a notable rise in demand for durable tile cutting solutions, particularly within the residential construction and remodeling sector. As homeowners increasingly prioritize high-quality finishes in kitchens, bathrooms, and flooring, precision tools like the Tile Cutting Machine have become essential. This shift reflects both an aesthetic preference and a growing awareness of the long-term value offered by well-installed tile surfaces.

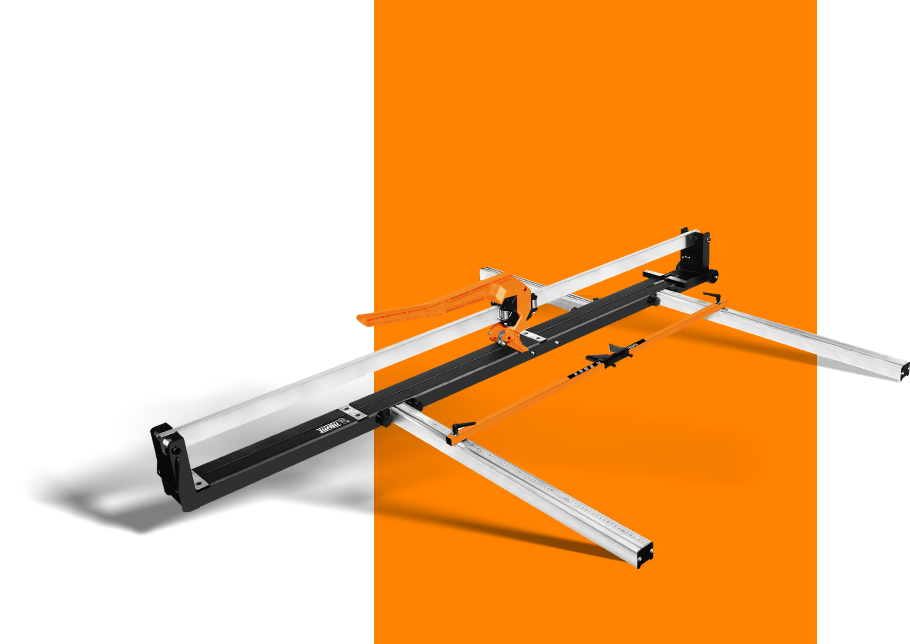

One key factor driving this trend is the growing accessibility of professional-grade tools for personal or small-scale use. Homeowners and small contractors alike are investing in reliable equipment to carry out their own renovations. Among these, the Tile Cutting Machine is widely appreciated for its ability to produce straight, clean cuts on a range of tile materials, including ceramic, porcelain, and stone. With designs evolving to accommodate user-friendly features, these machines now cater to a broader range of skill levels.

The increased popularity of ceramic tile in residential applications has also led to heightened interest in components that influence cutting accuracy and finish. The ceramic tile cutting wheel, a core element of manual and electric tile cutters, plays a crucial role in ensuring precise scoring and reduced breakage. As tiles become denser and more intricate in texture, demand has shifted toward wheels that can withstand continuous use without compromising the quality of the cut.

In urban housing developments and suburban home improvements, tiles are often selected for their durability and low maintenance. However, improper cutting can compromise the appearance and fit, pilot to material waste and inconsistent layouts. This makes the role of a well-calibrated Tile Cutting Machine even more significant. Manufacturers are responding by incorporating enhancements in build materials and engineering tolerances, ensuring machines can handle repetitive tasks with consistency.

Moreover, the ceramic tile cutting wheel has seen gradual improvements in its design and manufacturing process. Newer wheels offer smoother scoring with small chipping, even on glazed surfaces. This improvement is crucial for both aesthetic purposes and for less material damage during installation. The combination of a high-performance wheel with a stable Tile Cutting Machine results in fewer errors and a more efficient workflow, especially in home environments where time and resources may be limited.

Sustainability concerns have also played a part in influencing buyer preferences. With growing interest in less construction waste, precise cutting tools are favored for their contribution to efficient material use. The Tile Cutting Machine, when paired with a reliable ceramic tile cutting wheel, helps reduce tile wastage by achieving accurate dimensions in fewer passes. This not only benefits individual projects but also aligns with broader environmental goals in the building industry.

Additionally, many consumers now seek tools that are easy to maintain and store, given space constraints in residential areas. Compact designs with integrated features such as adjustable cutting guides and dust control are increasingly common. These features support the consistent use of the ceramic tile cutting wheel, ensuring it remains effective over longer periods without frequent replacements.

The rising demand for residential tile installations has led to a corresponding increase in the use of high-precision tools. The Tile Cutting Machine has emerged as a dependable solution for homeowners and contractors looking for reliability and ease of use. Coupled with an efficient ceramic tile cutting wheel, it enables accurate tile customization suited for modern design preferences. As the home improvement trend continues to grow globally, these tools are likely to remain at the core of residential construction practices.