Tile Tool Manufacturers Focus On Safety And Usability In Product Design Updates

2025-05-26

In recent years, manufacturers in the tile tool industry have shifted their attention toward improving both safety and user experience in their product lines. With changing demands from construction professionals and DIY enthusiasts alike, this shift is reflected in a new wave of updates to tools like the Tile Cutting Machine and the ceramic tile cutting wheel. These developments aim to address the practical needs of users working in increasingly diverse environments.

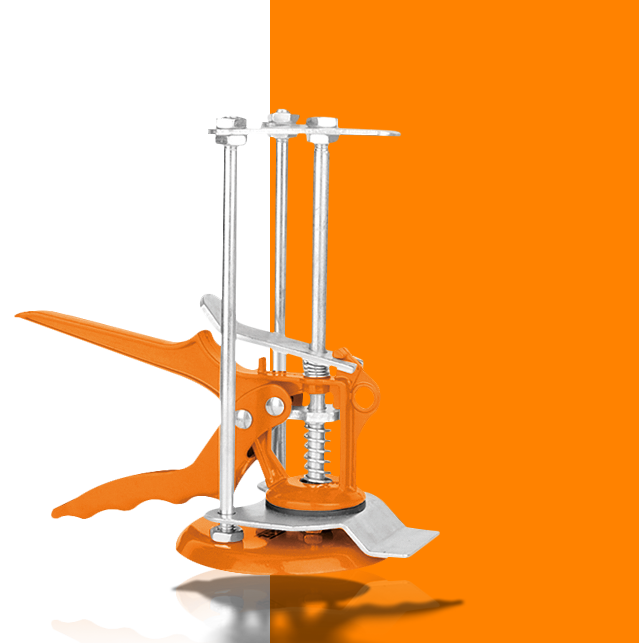

One of the major focuses has been making the Tile Cutting Machine more intuitive to operate while maintaining reliability across different tile materials. Previous models often required a steep learning curve, especially for one-time users. Newer versions now incorporate ergonomic grips, smoother slide mechanisms, and enhanced base stability to reduce accidents and improve cutting accuracy. These upgrades allow for more efficient workflows and reduce fatigue during extended use.

Safety improvements are particularly noticeable in the design of the ceramic tile cutting wheel. Manufacturers are experimenting with reinforced edges and improved heat resistance to handle the demands of repeated use. These enhancements not only less wear but also lower the risk of breakage, a common concern among users working on thick or uneven ceramic tiles. Some tools now also include built-in guards or shields to protect hands and reduce contact with moving components.

Versatility has also become a critical consideration in modern tile tools. For instance, the new Tile Cutting Machine designs are compatible with multiple tile sizes and thicknesses, allowing users to switch between materials without needing several separate tools. This adaptability is especially useful on job sites where different tile types are used for floors, walls, and decorative features. Adjustable cutting guides and dual-speed options further support a variety of tasks without compromising safety.

The ceramic tile cutting wheel has also seen updates that align with this trend. New wheel compositions feature advanced bonding agents that allow for cleaner cuts through dense materials. In addition, the cutting edges are being engineered to generate less dust and debris, improving air quality and visibility during operation. These factors contribute to a safer and more pleasant working environment, especially in enclosed or indoor spaces.

Another key trend is the integration of clearer visual indicators and tactile feedback in both the Tile Cutting Machine and associated accessories. For example, depth and angle adjustment knobs are now more responsive and easier to calibrate, less the chances of error. On some models, users receive visual cues when the blade or ceramic tile cutting wheel begins to wear, reducing the likelihood of inefficient or dangerous cuts due to dull edges.

Many of these changes stem from direct feedback from users, collected through trade shows, online reviews, and field testing. By closely monitoring how their products perform under real-world conditions, manufacturers are identifying opportunities to improve durability, precision, and above all, safety. This approach ensures that tools like the Tile Cutting Machine are continuously refined to better support both professionals and hobbyists.

At the same time, companies are taking steps to ensure that updates to tools such as the ceramic tile cutting wheel do not significantly raise costs. Affordability remains a key concern, and manufacturers are balancing advanced features with accessible pricing to stay competitive in a growing market. As more users seek tools that are dependable and straightforward to operate, maintaining this balance is essential.

The ongoing emphasis on usability and safety in tile tool design reflects a broader movement in the construction industry. As technologies evolve, so do user expectations. Tools like the Tile Cutting Machine and the ceramic tile cutting wheel are no longer judged solely by cutting strength but by how well they fit into the workflow, enhance safety, and reduce unnecessary effort. This shift marks a thoughtful step forward for an industry built on precision and performance.